Behind the Scenes at the ADG Print Shop...

At Anderson Design Group, we have always been involved in producing the posters we illustrate. When we started creating 18"x24" posters in 2004, all of our printing was done on offset printers. We would produce 500 to 1,000 prints of each new design and hope they would sell out. (14 years later, we still have some of those old prints laying around!) Eventually, digital printing came along, allowing us to do shorter runs of 10-20 posters whenever we came up with a new design. We would store them in our archive cave and pull them off the shelf each time someone placed an order. After we had created more than 800 designs, we started to run out of storage space—and locating certain prints became a dizzying feat. Here is a shot of 1/2 of our poster cave... (and this is the organized section!)

In 2016, we began to offer all of our designs in 2 sizes: 18x24 and 11x14. The only way to do this was to move to a print-on-demand model. We would create new art, store the digital art files on a server, and a printing company across town would print posters for us, roll them, and ship them to our customers.

This new model had its pros and cons. While it was wonderful to focus only on creating new art, we became separated from the rest of the process. We missed creating a design, seeing it produced, inspecting each print, touching the paper, even smelling the fresh ink. We missed rolling a new print, tucking it snugly into a tube, and thinking about the person who ordered it: what their reaction would be once they saw their poster or gave it away as a gift. If a mistake was made by the print vendor or fulfillment house, we would only find out about it after a customer told us about their sub-par experience.

We love illustrating and designing poster art. But we also love the entire process of engaging with our fans and customers, overseeing the production process, and hand-writing thank you notes to the special folks who like our art. We also enjoy adding new products and size formats, but that is hard to do when someone else is doing the printing and shipping!

So to get back to our roots and return to a more hands-on approach to our whole creative process, we hired an architect and made plans to construct a brand new state-of-the-art print shop and fulfillment center on the ground floor of our building.

Construction was supposed to start in July, but thanks to a lengthy permit process, we got started in September—just 2 months before our busiest time of year! As a small, family-owned-and-operated business, we had to wear lots of hats as we trained ourselves to run the new printing equipment, selected shelving and workshop fixtures, studied up on networking all of our printers and computers, and steered clear of sub-contractors as they destroyed part of our building and slowly put it back together.

Here are some photos of the transformation process...

Wouldn't you know it, we were able to move in the day before we left town for Thanksgiving. We came back just in time to try out all of the new equipment during our death-defying Black Friday/Cyber Monday weekend sale. Thankfully, everything worked, and we produced and shipped over 1,000 posters in one week—everything from cute little 8x10 mini prints to gorgeous 36x48 jumbo prints.

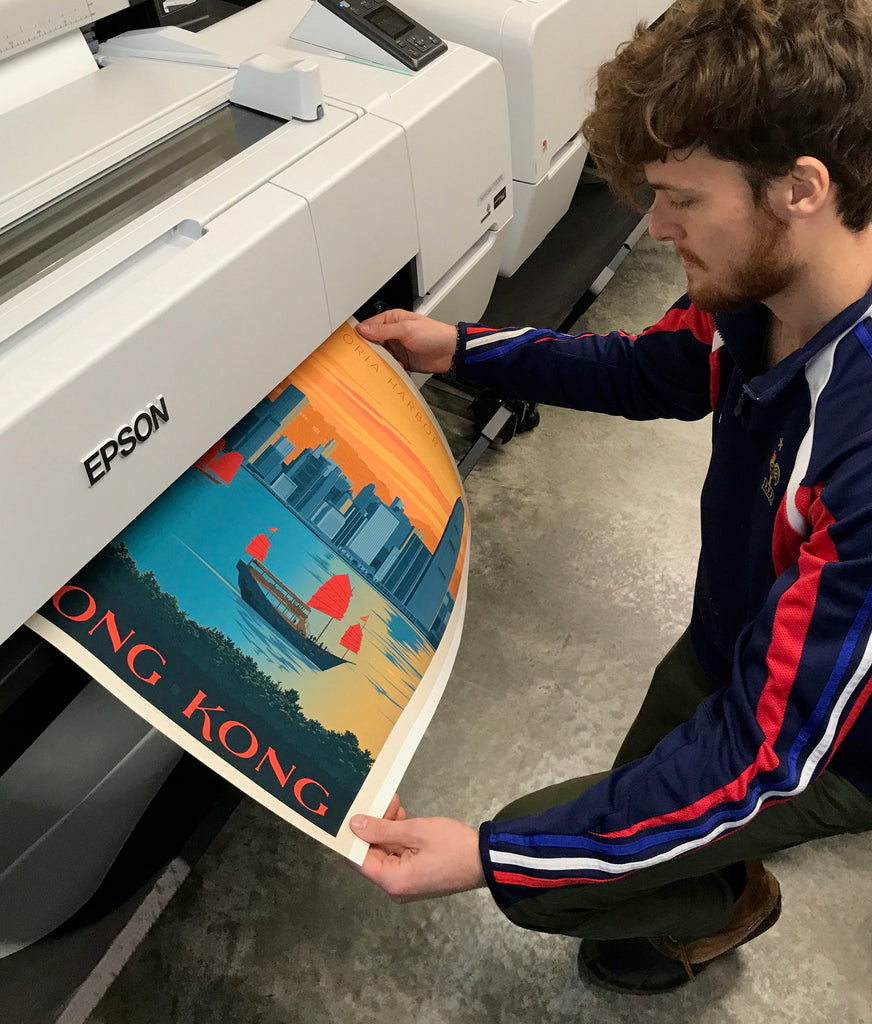

What a difference, too! Our new Epson printers produce insanely rich and colorful prints on gallery-grade uncoated paper. The prints are no longer heat-sensitive, so they can be dry mounted by framers. Our art has never looked better, and we have never been more satisfied with the print quality. And most importantly of all, our customers have never been more happy decorating with our designs!

Here is a peek at a typical workday at Anderson Design Group now that our new print shop is up and running:

1. Joel directs the process of creating new poster designs. In-house staff artists Aaron and Derek create 1-2 new designs each week. Once a new design is finished, Joel adds it to our ever-growing catalog of 1,500+ designs, and publishes each new poster on our site. After a design is published, customers from all over the world can order it at www.ADGstore.com.

2. When customers have questions, Molly has a cheerful and helpful answer.

3. Once an order is placed, Heidi prints out the customer's order info along with a shipping label.

4. Nathan and Molly send custom-print orders from each purchase to the printshop, formatting our art to fit the specific print size that was requested. (If our art was ordered as a metal sign or canvas, the print order is sent to our vendor partner in Texas.) If it is an order for one of our 5 different print sizes, we cue up the Epson printers and print each order one at a time.

5. Molly keeps the process organized. Nathan or Benji trims each print by hand.

6. They carefully roll each print, place it in a protective sleeve, say good-bye to it as they prepare to ship it to a happy home where it will be displayed proudly by the new owner.

7. If the customer is one of the lucky few, Benji will doodle a hand-drawn Thank-You on the packing slip!

8. Nathan or Benji will place a mailing label and an official ADG seal of quality on the tube, and load up another day's worth of art to be shipped all over the USA and beyond.

9. When another day of work is done in the print shop, Benji enjoys dancing to MoTown music.

Thank you SO much for your love & support as we've grown as a design studio & print shop. We look forward to serving you with plenty of fresh prints in 2019. Cheers & happy New Year!

← Older Post Newer Post →